7 QC Tools you should use to improve your Garments/Sweater product

quality:

7 QC (Quality Control) tools

are very effective for Garments/Sweater or any other types of the factory to

solve almost every type of problem in a factory operation. These are the tools

of troubleshooting quality issues, based on numeric value. 7 QC tools in Garments/Sweater

industry is a set of data analysis tools used to support continuous quality

improvement efforts. If you can use these seven fundamental tools, then

definitely quality control will be effective for your company.

7 QC Tools in Garments/Sweater

Industry:

Histogram

Check Sheet (Daily Inspection

Finding Report)

Cause-and-Effect Diagram

Pareto Chart

Scatter Diagram

Control Chart

Stratification

7 QC Tools in Garments/Sweater

Industry

Benefits of 7 QC Tools:

Improve management decision

making skills

Collect, present, Identify and

analyses data

Implement Six Sigma

Control cost of poor quality

Reduce variations and improve

quality

Reduce defects and improve

production

Reduce cycle time and improve

efficiency

Continuous quality improvement

Encourages teamwork and

confidence

Enhances customer satisfaction

through improved quality product

Explanation of 7 QC Tools for Garments/Sweater

Industry

Histogram:

Histogram is also a bar chart.

It is a graphical chart based on numeric value for showing frequency

distribution of database. People become confused among Histograms and Bar

Charts. A histogram is used for continuous data, where the bins represent

ranges of data, while a bar chart is a plot of categorical variables. Some

authors recommend that bar charts have gaps between the rectangles to clarify

the distinction.

Check Sheet (Daily Inspection Finding Report):

The Check Sheet/Tally sheet is

a simple document that is used for collecting data in real time and at the

location where the data is generated. The document is typically a blank form

that is designed for the quick, easy, and efficient recording of the desired

information, which can be either quantitative or qualitative. When the

information is quantitative, the check sheet is sometimes called a tally sheet.

A tally sheet to collect data on frequency of occurrences which custom designed

by user.

Cause-and-effect diagram

(Ishikawa Diagram / Fishbone Diagram):

Cause-and-effect diagram is

look like a fish that’s why it’s called Fishbone Diagram, also called Ishikawa

diagram, herringbone diagrams or Fishikawa diagrams, a visualization tool for

categorizing the potential causes of a problem in order to identify its root

causes. Causal diagrams created by Kaoru Ishikawa that show the causes of a

specific event. Dr. Kaoru Ishikawa developed the “Fishbone Diagram” at the

University of Tokyo in 1943.To break down (in successive layers of detail) root

causes that potentially contribute to a particular effect. This diagram is used

in process improvement methods to identify all of the contributing root causes

likely to be causing a problem.

How to Work on Fishbone

If you find a problem and want

to make fishbone diagram. First need brainstorming about the defect to find out

types of causes based on 6 basic things. These are:

Machine

Manpower

Environment

Method

Materials

Measurement

Brainstorm all the possible

causes of the problem. Ask: “Why does this happen?” As each idea is given, the

facilitator writes it as a branch from the appropriate category. Causes can be

written in several places if they relate to several categories. For example you

can see fishbone in the below:

Pareto Chart (80/20 Rule):

A Pareto chart is a bar graph.

The lengths of the bars represent frequency or cost (time or money), and are

arranged with longest bars on the left and the shortest to the right. In this

way the chart visually depicts which situations are more significant.

The Pareto principle

The Pareto principle (also

known as the 80–20 rule, the law of the vital few, and the principle of factor

sparsity) states that, for many events, roughly 80% of the effects come from

20% of the causes. More generally, the Pareto Principle is the observation (not

law) that most things in life are not distributed evenly. In Garments/Sweater

industry, you can see the data in the below that first 5 defects covered 50% of

total defect. So 80-20 rules will not cover all-time 80% problem for 20% causes.

It can mean all of the following things:

20% of the defects number

accumulate 80% of the total defects

20% of the operator produce 80%

of the defects

20% of the customers create 80%

of the revenue

Pareto for Garments/Sweater

Industry

Scatter Diagram:

The scatter diagram graphs

pairs of numerical data, with one variable on each axis, to look for a

relationship between them. If the variables are correlated, the points will

fall along a line or curve. The better the correlation, the tighter the points

will hug the line. The scatter diagram Collect pairs of data where a

relationship is suspected.

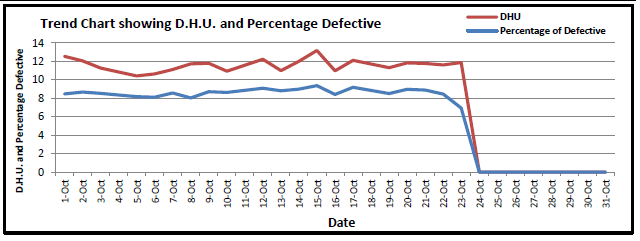

Control Chart (Shewhart

Chart):

Control charts, also known as

Shewhart charts or process-behavior charts, are a statistical process control

tool used to determine if a manufacturing or business process is in a state of

control. A control chart shows how data frequency changes, defects trends and

compares with previous time record. Control chart monitor process and

hypothetical prediction. Garments/Sweater industry need to reduce defect

frequency to get quality improvement.

Control Chart for Garments/Sweater:

Stratification (Divide and

Conquer), can be alternative of flow chart or run chart

Stratification is a method of

dividing data into subcategories and classify data based on a group, division,

class or levels that helps in deriving meaningful information to understand an

existing problem. The main purpose of Stratification is to divide the data and

conquer the meaningful information to solve a problem. The visual nature of the

chart makes patterns jump out.

Implementation of 7 QC Tools

To implement these tools in

your industry, you must have to do Pareto, Fishbone for every section. Result

publishes visibly in each line or area in board. People will be conscious to

reduce defect. There improvement tracking on control chart also visible for

each line/area. You have to find root cause from the root level for cause and

effect diagram. Data and data collection must be accurate. Every section has to

be taken corrective action based on quality data. Every section must do a

quality meeting to take new decision for quality control at least once per

month.

1 Comments

Good tools, can you support us with this tools. Iitgarmentsindia.

ReplyDelete